introduction

金屬氮化物硬膜實驗室

於1994年成立於國立清華大學工程與系統科學系。目前實驗室師資陣容為喻冀平教授、黃嘉宏教授兩位,研究生成員有博士班3位、碩士班8位。主要研究經費來源為國科會及原能會。截至目前(2009)為止在SCI國際期刊共發表41篇論文,每篇平均引用率超過12次,並在國際會議上發表過40篇論文。自1996年至目前,本實驗室共畢業3位博士班與36位碩士班學生。

始

本實驗室於1994年購入一套中空陰極放電式離子鍍膜機(HCD-IP),氮化鈦(TiN)為最先選擇之鍍著材料,1998年後加入氮化鋯(ZrN)薄膜的研究。使用之基材有AISI 304不鏽鋼、D2 工具鋼、以及(100)矽晶片。為提高尋找最佳製程參數之效率,於1996年起採用田口式實驗規劃法,尋找最適製程參數範圍,並依重要製程參數進行一次一因子實驗,以得最佳製程參數。

起

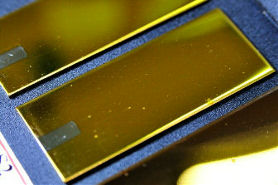

目前氮化鈦與氮化鋯薄膜結構及性質間之關係已詳細研究,並進一步與製程參數如鍍膜溫度、膜厚、基板偏壓、氮氣分壓等相關連。在此同時,其他性質,如殘餘應力、薄膜織構、腐蝕抗性、附著性、電性等均已研究。於2000年本實驗室再添入一套非平衡磁控濺鍍機,進行氮化鈦與氮化鋯薄膜研究。由於奈米科技的興起,本實驗室在過去八年間之研究重點在於金屬氮化物與氮氧化物奈米晶薄膜的製備與性質研究,並探討厚度低於400 奈米 之奈米晶薄膜的機械與腐蝕性質。

躍

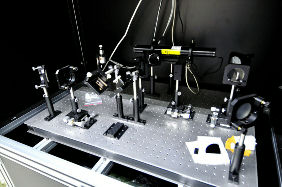

2006 年本實驗室再購入第三套鍍膜機,本設備具有三支非平衡磁控濺鍍鎗,具有多種靶材同時濺鍍之能力,為本實驗室的研究方向增添很大的彈性。目前除上述之既有研究方向外,並正發展新的研究方向,主要著力於功能薄膜之製程與性質研究,如:非晶形金屬薄膜,軟性基材防水薄膜,與金屬氮氧化物薄膜之電性與鐵電性質研究。

The Metal Nitride Hard Coating (MNHC) laboratory was established in 1994 in the Department of Engineering and System Science, National Tsing Hua University. Members in the MHNC lab include two professors, Prof. Jia-Hong Huang and Prof. Ge-Ping Yu, and 11 graduate students (3 PhD and 8 MS students). The research funding sources are mostly from governmental support, National Science Council and Atomic Energy Council of the ROC. Up to the present stage (2009), there have been 41 research papers published in the prestigious SCI international journals, with average citation times more than 12, and 40 papers have been presented in the international conferences. Three PhD and 36 MS students have graduated from this lab since 1996.

A hollow cathode discharge ion plating (HCD-IP) apparatus was installed in this lab in 1994, and titanium nitride (TiN) was selected to be the first coating material. In 1998, zirconium nitride (ZrN) thin film was added in the research topic. A few substrate materials have been used including AISI 304 stainless steel, D2 tool steel, and Si wafer. To increase the efficiency of seeking proper processing parameters, Taguchi design of experiment (DOE) method was introduced in 1996. Subsequently, single-variable experiments on the significant parameters were performed to optimize the coating processing. Structure and property relationships of TiN and ZrN thin films have been extensively studied and further related to the processing parameters such as deposition temperature, film thickness, substrate bias, and nitrogen flow rate. Other properties such as residual stress, texture, corrosion protective capability, adhesion of the film, electrical resistivity and hardness, were also investigated. In 2000, an unbalanced magnetron (UBM) sputtering machine was added to facilitate the research in TiN and ZrN thin films. Due to the emergence of nanotechnology, the research direction during the past 8 years has been focused on the nanocrystalline thin films of transition metal nitrides and oxynitrides, especially on the mechanical and corrosion protection properties for the films with thickness less than 400 nm. In 2006, the second sputtering machine with three 2-in sputtering guns was installed, which extended our research topics to functional coatings. In addition to the abovementioned topics, the current research performing subjects in MNHC lab are: amorphous metallic alloy thin films, water-proof thin films on flexible substrate material, electric and ferroelectric properties of metal oxides and oxynitrides thin films.

The major contributions of the MNHC lab are (1) using the in-situ strip-tension method in SEM to measure the interfacial shear stress between film/substrate interface, and using X-ray diffraction to measure the residual stress and to correct the result of interfacial shear stress, (2) investigating the corrosion properties using both potentiodynamic scan and 500-hour salt spray test, and successfully correlating the results of the two tests, (3) developing the modified sin2y method of XRD to measure the residual stress of textured thin film and further related the stress to the texture of the thin film determined by XRD pole figure, (4) linking and applying both Taguchi DOE and single-variable methods on the coating processing and developing optimization approach in the multi-variable coating processes, and (5)combining laser curvature and XRD sin2y method to measure the strain tensors and elastic constants of nitride thin films.

The facilities in the MNHC lab includes an HCD-IP apparatus, UBM sputtering machine, SSRT, atomic force microscope (AFM), nanoindenter, nanoscrather, potentiodynamic scanning instruments, salt spray tester, high temperature tube furnace with controlled atmosphere. The other supporting facilities from the ESS department are 200-kV TEM, FEG-high resolution SEM, SEM with in-situ tensile stage and X-ray diffractometer.